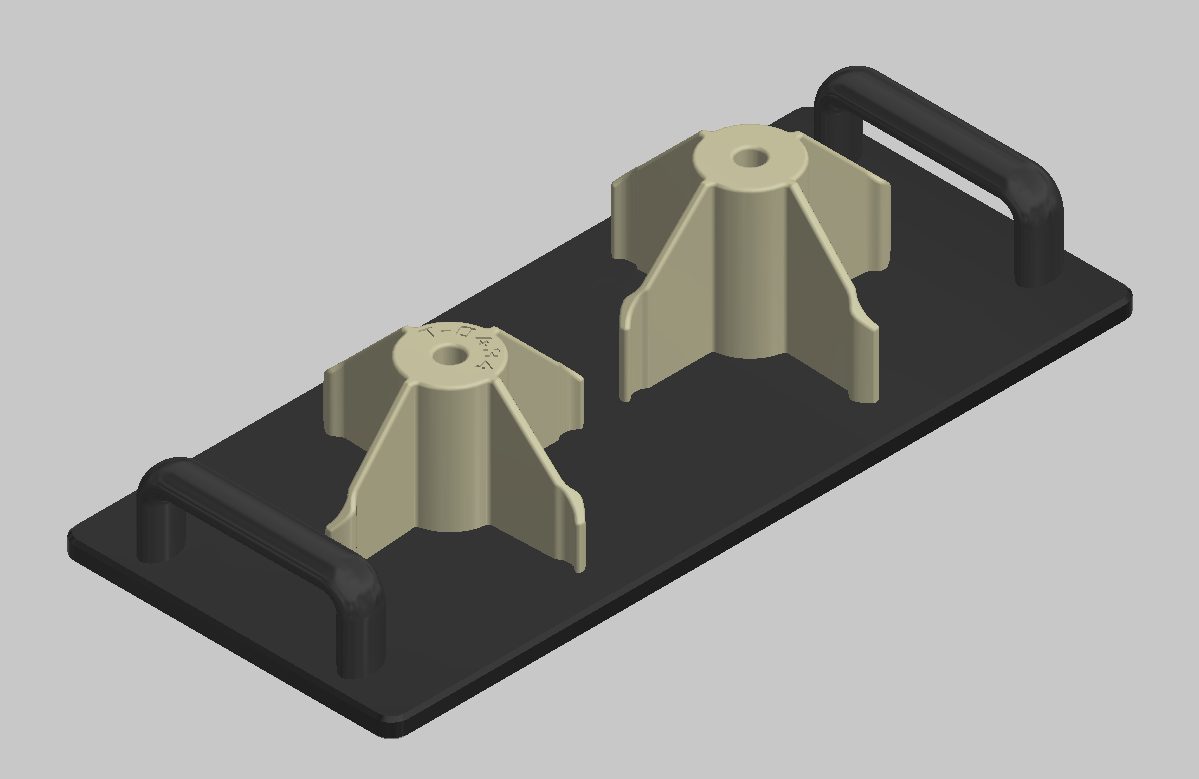

Costom jig & fixture design

Our experienced team specialises in designing bespoke jigs, fixtures, and tooling solutions crafted to enhance your production’s efficiency, accuracy, and repeatability. Leveraging a strong foundation in hands-on manufacturing and tool making, we deeply understand the critical practicalities of alignment, clamping, and precise positioning required across various processes such as welding, machining, and assembly.

Every design we deliver is thoughtfully developed with real-world applications in mind, ensuring it is user-friendly, durable, and seamlessly integrates into your existing workflow. By tailoring solutions to your specific production needs, we help reduce errors, minimise setup times, and improve overall product quality — driving your operations toward consistent and cost-effective manufacturing.

Background:

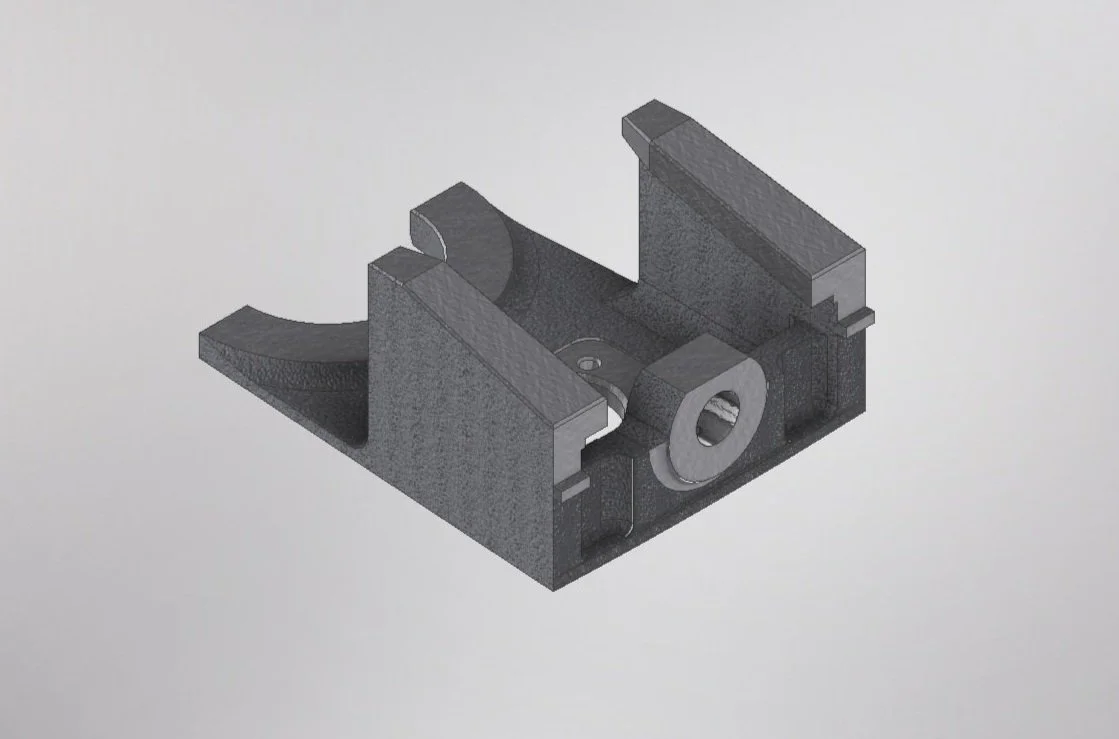

A customer approached us with a critical machine part used to clamp material inside a press. The existing part was damaged, and the supplier’s lead time for a replacement was approximately 12 weeks. This long wait risked significant downtime and production delays for the customer.

Objective:

To provide a rapid replacement part that meets the original specifications and restores the machine’s functionality in the shortest possible time.

Process:

Upon receiving the damaged part, our team began by carefully measuring its dimensions. Using these measurements, we created an accurate 3D model of the component. The design was developed using AutoCAD software, which allowed us to create precise digital drawings. We then converted the AutoCAD file into a format compatible with 3D printing technology.

Leveraging advanced 3D printing, we manufactured the replacement clamp part. After printing, the part underwent thorough verification to ensure dimensional accuracy and fit.

Outcome:

The replacement part was delivered to the customer within 72 hours of receiving the original damaged part, dramatically reducing the downtime compared to the original 12-week lead time.

Conclusion:

By utilising 3D modelling and printing technology, we successfully provided a rapid and accurate replacement for a critical machine component. This approach not only minimised operational disruption for the customer but also demonstrated the potential of additive manufacturing in urgent repair scenarios.

Case Report

Clamping jig replacement